For those with hydraulic elevators, the replacement of a hydraulic jack can be a lengthy and expensive process. However, it is becoming decidedly more rare given changing techniques and the imposition of new codes. Here we try to give an overview of what is at play here and the evolution of the procedures for dealing with and preventing the loss of a hydraulic jack.

WHAT IS THIS ABOUT?

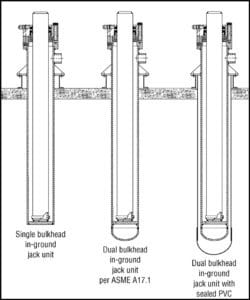

In 1971 the elevator code was changed to provide in-ground hydraulic cylinders with a safety bulkhead at the bottom of the cylinder. Older jacks were single bottom. The picture shows the evolution of the design as follows:

(a) an older single bottom jack; (LEFT)

(b) the newer code-compliant double bottom (MIDDLE)

(c) the last is a double bottom with a corrosion-protective PVC jacket around the metal cylinder(RIGHT)

The system as shown in the double bottom, PVC jacketed makes the bottom of the cylinder double walled. There is a small orifice between the two that only allowed a certain amount of oil to escape at a set rate. This only allowed the elevator to descend at or below 15 fpm.

Many States or other Authorities Having Jurisdiction(“AHJs”) have mandated that all single bottom jacks have been replaced. For that reason, the frequency of jack replacements has been lessened. Nevertheless, it still is not an uncommon occurrence in our field.

WHY ALL THE CONCERN?

As stated, the present code requires a double bottom jack. However, AHJs have also mandated a retrofit of existing systems. Below is an explanation of the “why” of all this activity.

REDUNDANCY

The elevator industry is in small part guided by a belief in achieving the desired result and avoiding failures through redundancy. So, while it may be sufficient to achieve your aim one way; achieving it twice makes failure geometrically less possible. In no small part, this probably influenced the code changes referenced in the ground.

ELECTRICITY IN THE GROUND (yes, really)

The primary reason for jack failure arises is from a corrosive hole in your hydraulic cylinder. This is most often caused by electrolysis. Electrical charge in the ground is normal and to be expected. It usually presents over time. However, this same process can certainly accelerate from a lightning strike which while not uncommon is certainly not the primary source of the hole or fissure. In either case, corrosion from the unprotected cylinder being buried in the ground and subjected to electrical charges. It most often occurs at the very bottom, hence the change in the elevator code.

The primary reason for jack failure arises is from a corrosive hole in your hydraulic cylinder. This is most often caused by electrolysis. Electrical charge in the ground is normal and to be expected. It usually presents over time. However, this same process can certainly accelerate from a lightning strike which while not uncommon is certainly not the primary source of the hole or fissure. In either case, corrosion from the unprotected cylinder being buried in the ground and subjected to electrical charges. It most often occurs at the very bottom, hence the change in the elevator code.

You can see the hole in the above cylinder. This is a double-bottom jack, and you can now see why it’s important to have the double bottom. Only a single bottom oil could escape at a faster rate causing the elevator to descend at a higher speed. On existing hydraulic jacks that were installed before 1970, and are still in operation there are other avenues rather than replacement. Contact your sales representative about your options. But once the system fails replacement is the only option. This is truly a case of what you can’t see that can hurt you.

ENVIRONMENTAL

The code also changed due to environmental concerns about oil leaking into the ground in case of a leak. It is interesting that the code changes followed shortly after the passage of the Clean Water Act. One cannot help but think that some of the same concerns entered into the minds of the code authors. However, it is nice that the new system allows for a more systematic way to harvest and handle oil consistent with EPA and State mandates. It is worth noting that Environmental contractors play an important part in handling and disposing of oil and oil-affected soil. It is interesting to note that they often recycle harvested oil and re-sell it in the market for the same or similar uses.

We hope that you have found the above informative. Thank you for your consideration.

Authored by Keith Gaut – Field Supervisor and Safety Manager for Bagby Elevator Company